-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

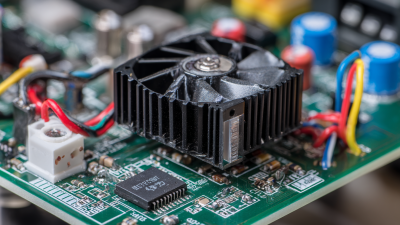

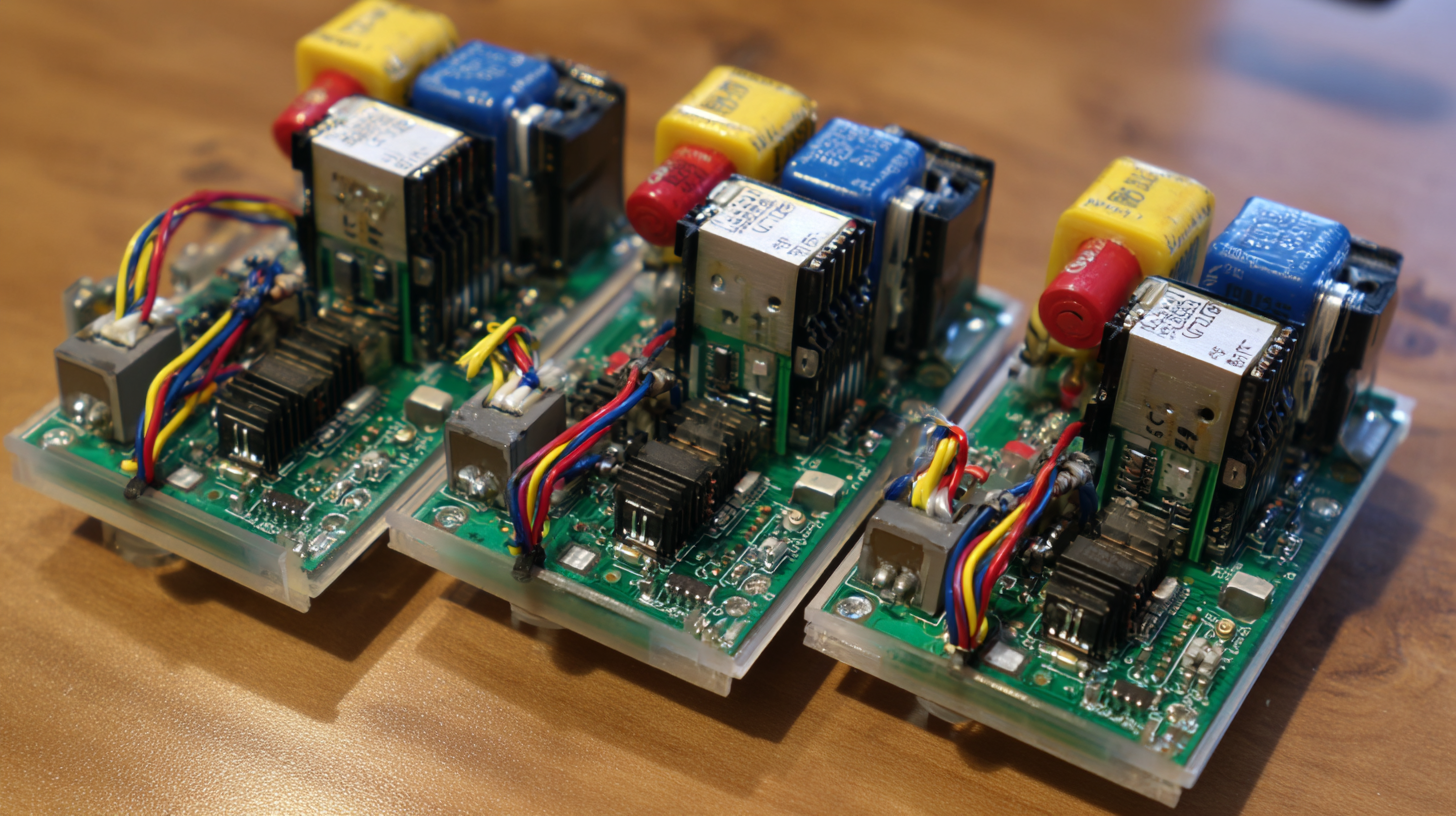

In the rapidly evolving landscape of automation technology, stepper motor drivers play a crucial role in enhancing the performance of stepper motors. These devices are integral to applications requiring precise motion control, such as robotics, CNC machines, and 3D printing. According to a recent market analysis by Mordor Intelligence, the stepper motor driver market is expected to grow significantly, projecting a CAGR of over 6% from 2021 to 2026. This growth underscores the increasing demand for high-performance stepper motor drivers that offer advanced features and reliability.

As we look towards 2025, it's essential to identify the top contenders in the market that provide unmatched performance and innovative capabilities. Factors such as current ratings, microstepping resolution, and integrated protection features are critical considerations for engineers and designers when selecting the right stepper motor driver. In this context, recognizing the leading products will not only facilitate more efficient designs but also contribute to the enhancement of operational efficiency across various industries. In this article, we will explore the top five stepper motor drivers that stand out in 2025, highlighting their unique features and performance metrics that set them apart from the competition.

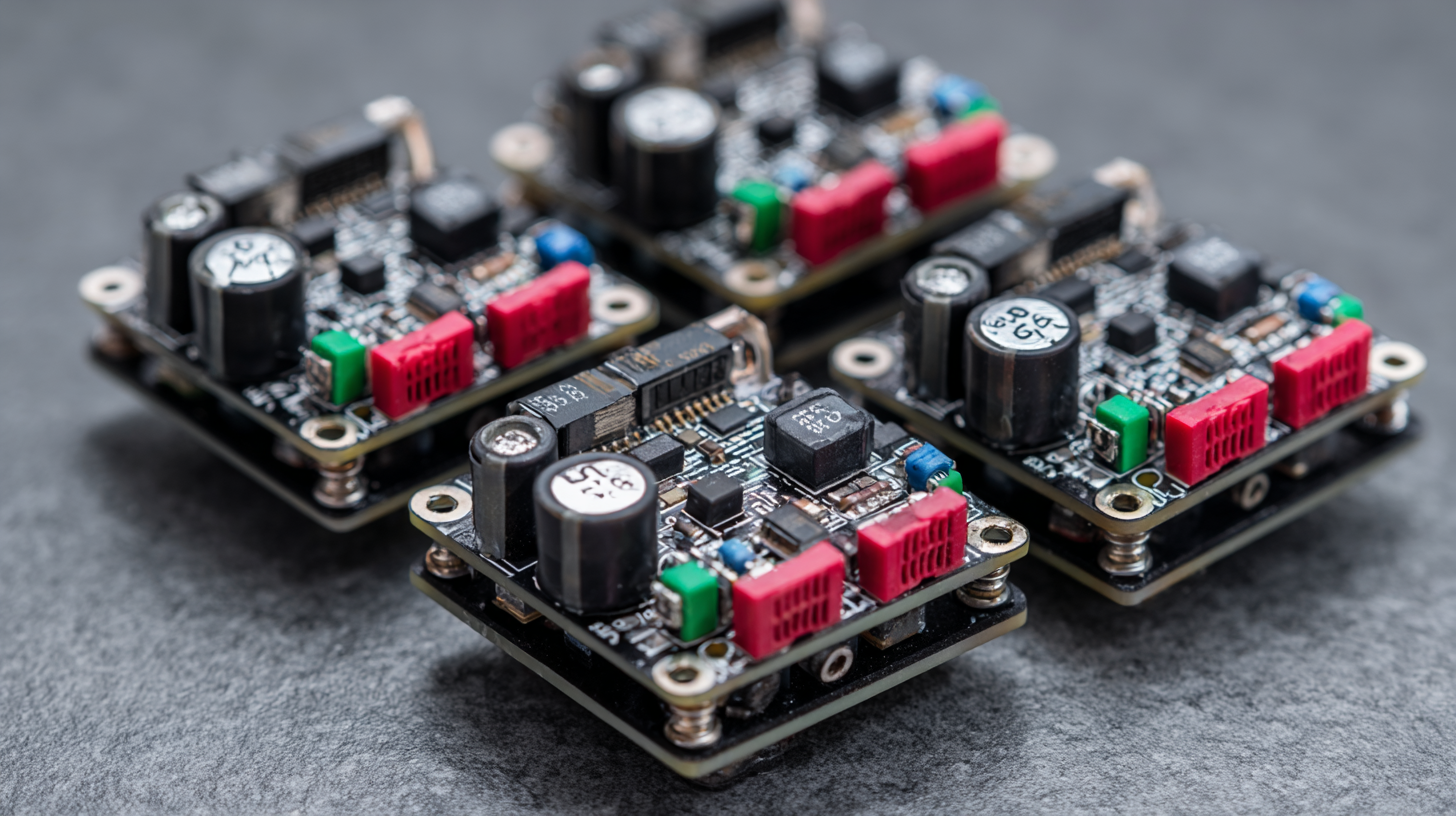

When selecting the best stepper motor drivers in 2025, it’s essential to consider a few critical criteria that differentiate high-quality products. Firstly, the driver’s performance capabilities, such as current rating, voltage compatibility, and microstepping options, are pivotal. A driver with higher microstepping resolutions provides smoother motion and increased positional accuracy, which is crucial for applications requiring precision.

Tips: Look for drivers that allow adjustable current settings, as this can enhance efficiency and reduce heat generation. Additionally, drivers with integrated protection features, like overcurrent and thermal shutdown, can safeguard your motor and prolong its lifespan.

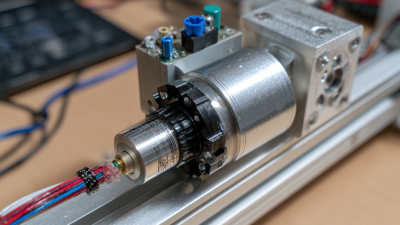

Another important factor is the ease of integration with existing systems. Drivers that offer user-friendly interfaces and comprehensive documentation can significantly simplify the setup process. Moreover, connectivity features, such as compatibility with popular control platforms and communication protocols, should be prioritized to ensure seamless operation.

Tips: To streamline your selection process, evaluate the availability of developer support, tutorials, and an active community. This can greatly assist in troubleshooting and optimizing driver performance.

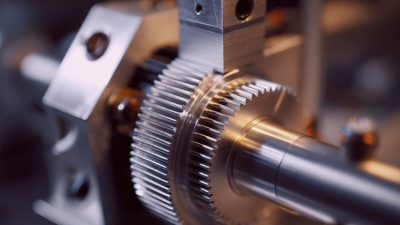

When selecting the best stepper motor drivers for 2025, understanding the key performance metrics is crucial. These metrics include torque output, current control capabilities, and thermal management. High torque output is essential for applications requiring strong acceleration and deceleration, ensuring optimal performance under varying load conditions. Drivers that utilize advanced current control techniques can dynamically adjust power delivery, enhancing efficiency and minimizing heat generation, which is vital for maintaining long-term reliability.

Another significant metric to consider is microstepping resolution, which impacts the smoothness and precision of motor movement. Drivers offering higher microstepping capabilities enable finer control over motor positioning, making them suitable for applications in robotics and CNC machinery where accuracy is paramount. Additionally, features such as built-in diagnostics and protection mechanisms contribute to overall system robustness, preventing potential failures and minimizing downtime. By focusing on these key performance metrics, users can make informed decisions when choosing the top stepper motor drivers suited for their specific needs in 2025.

| Driver Model | Max Current (A) | Supply Voltage (V) | Step Resolution | Microstepping Capability | Control Interface |

|---|---|---|---|---|---|

| Model A | 2.5 | 50 | 1.8° (200 steps/rev) | Up to 256 | UART, SPI |

| Model B | 3.0 | 60 | 0.9° (400 steps/rev) | Up to 512 | I2C, PWM |

| Model C | 2.0 | 48 | 1.8° (200 steps/rev) | Up to 128 | UART |

| Model D | 4.0 | 80 | 1.2° (300 steps/rev) | Up to 256 | SPI |

| Model E | 1.5 | 30 | 1.8° (200 steps/rev) | Up to 64 | PWM, UART |

As we delve into the advanced features driving innovation in the top stepper motor drivers of 2025, it's evident that remarkable strides have been made in performance and efficiency.

Manufacturers are increasingly focusing on integrating smart technology, such as real-time monitoring and adaptive control algorithms, which enhance the responsiveness of stepper motors in various applications.

These innovative features not only simplify operational complexity but also significantly extend the lifespan of the equipment by optimizing power delivery and minimizing overheating during high-demand tasks.

Moreover, the incorporation of advanced communication protocols, like CANopen and EtherCAT, allows for seamless integration into modern automation environments. This connectivity ensures that the stepper motor drivers can be monitored and managed remotely, providing engineers with valuable insights into performance metrics and conditions.

Enhanced programmable functionality further empowers users to customize motor control strategies, tailoring operational parameters to specific application requirements, thus unlocking unmatched versatility and productivity in industrial settings.

The convergence of these advanced features positions 2025’s top stepper motor drivers at the forefront of technology, catering to the evolving demands of diverse industries.

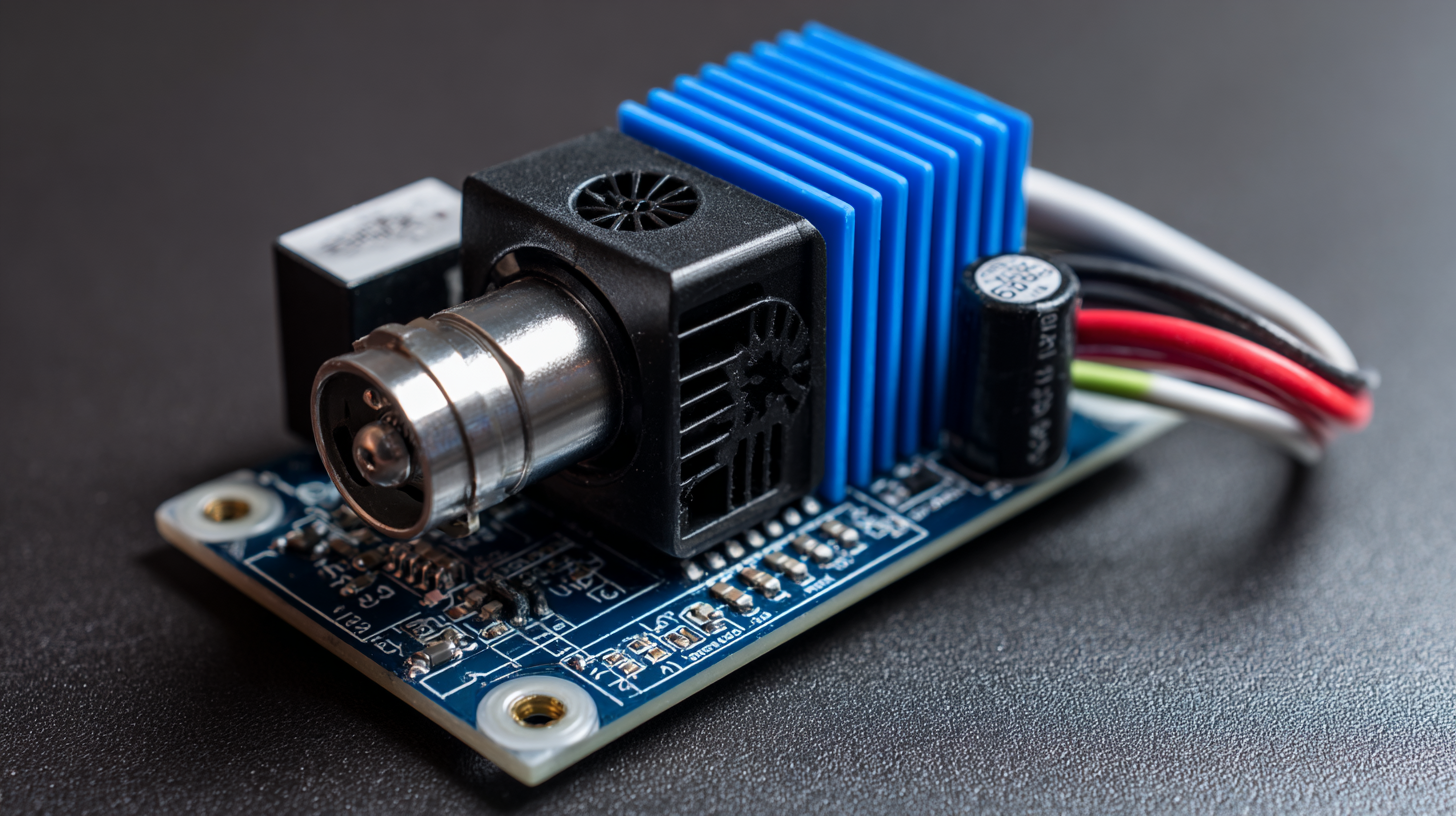

In the rapidly evolving field of motion control, the efficiency and thermal management of stepper motor drivers have become critical factors in determining their performance. According to a recent report by Allied Market Research, the global stepper motor market is expected to reach $3.4 billion by 2025, highlighting the growing demand for drivers that not only provide exceptional torque but also optimize energy consumption and minimize heat generation. Leading manufacturers are responding to this demand by implementing advanced thermal management techniques such as integrated heatsinks and adaptive current control, which can reduce thermal buildup by up to 30%.

Moreover, a study conducted by the International Journal of Electrical Engineering, which examined various stepper motor drivers, indicated that those equipped with high-efficiency MOSFETs performed better in both speed and torque under high-duty cycles. Drivers with a lower RDS(on) have shown to reduce power losses significantly, directly correlating to enhanced operational efficiency. By analyzing the latest advancements in thermal dissipation materials and techniques, companies can ensure that their products maintain optimal performance even in demanding applications, paving the way for the next generation of stepper motor drivers.

This chart compares the efficiency and thermal management of the top 5 stepper motor drivers for 2025. The efficiency is measured in percentages, while the thermal management is represented in degrees Celsius. Driver E shows the best efficiency, while Driver B exhibits superior thermal management.

The evolution of stepper motor driver technology by 2025 will be significantly influenced by the integration of IoT and AI. With the proliferation of smart devices, the demand for advanced motor control systems is set to rise. IoT enables seamless communication between devices, allowing stepper motors to be remotely monitored and controlled. This connectivity not only enhances operational efficiency but also enables predictive maintenance, minimizing downtime and improving productivity.

Artificial Intelligence will further revolutionize stepper motor driver functionality. By harnessing data analytics and machine learning, AI can optimize performance based on real-time input, adapting to varying loads and conditions. This capability allows for smarter power management, enhancing energy efficiency while reducing operational costs. As these technologies continue to converge, users can expect drivers that not only respond to immediate operational demands but also anticipate future needs, driving innovation across industries and applications.