-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

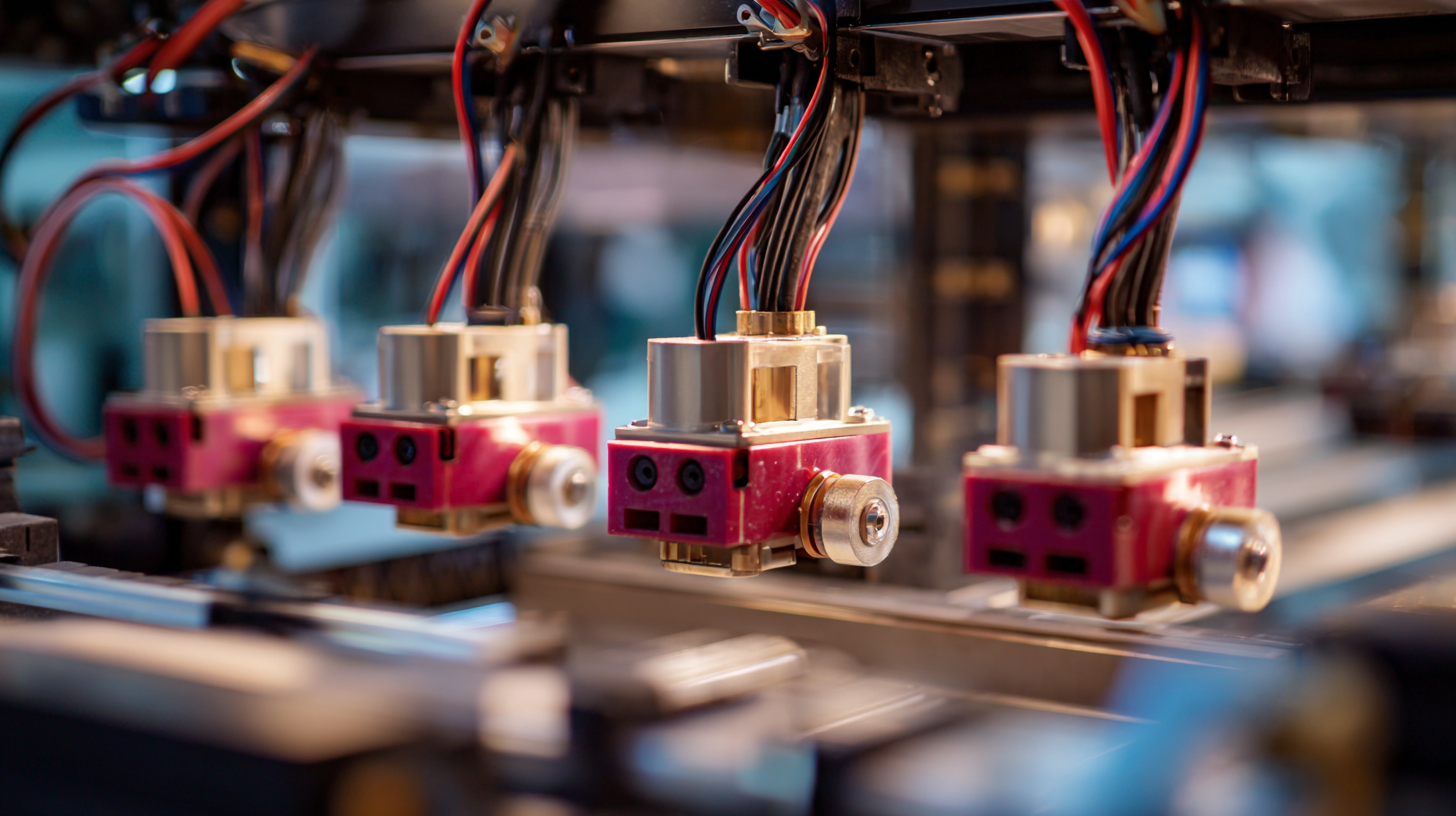

Stepper Motors are crucial components in various automation systems, robotics, and manufacturing processes, driving precision and reliability in motion control. According to a recent industry report by MarketsandMarkets, the global stepper motor market is projected to grow from USD 2.23 billion in 2021 to USD 3.75 billion by 2026, reflecting an impressive CAGR of 10.5%. This surge in demand is attributed to the increasing implementation of automation across multiple sectors, including electronics, automotive, and healthcare. As end-users seek more efficient and versatile solutions, understanding the top performance metrics of the best stepper motors becomes essential for making informed decisions.

In this blog, we unveil critical technical specifications and compare leading models, offering insights into their performance parameters and guiding you through the selection process for optimal applications.

When selecting the best stepper motors for your project, understanding key performance metrics is crucial. Torque is one of the most critical factors, as it determines the motor's ability to hold or move loads. It is essential to assess both the holding torque, which is the motor's ability to maintain position when energized, and the dynamic torque during movement, as these metrics influence overall performance and efficiency in various applications.

Speed is another vital metric in the comparison of stepper motors. The ability to achieve higher speeds can enhance productivity, especially in automation and robotics. However, it’s important to balance speed with torque, as a motor's ability to maintain torque decreases at higher speeds. This trade-off makes it essential for engineers to analyze the performance curves of different motors to select the right one tailored to their specific needs.

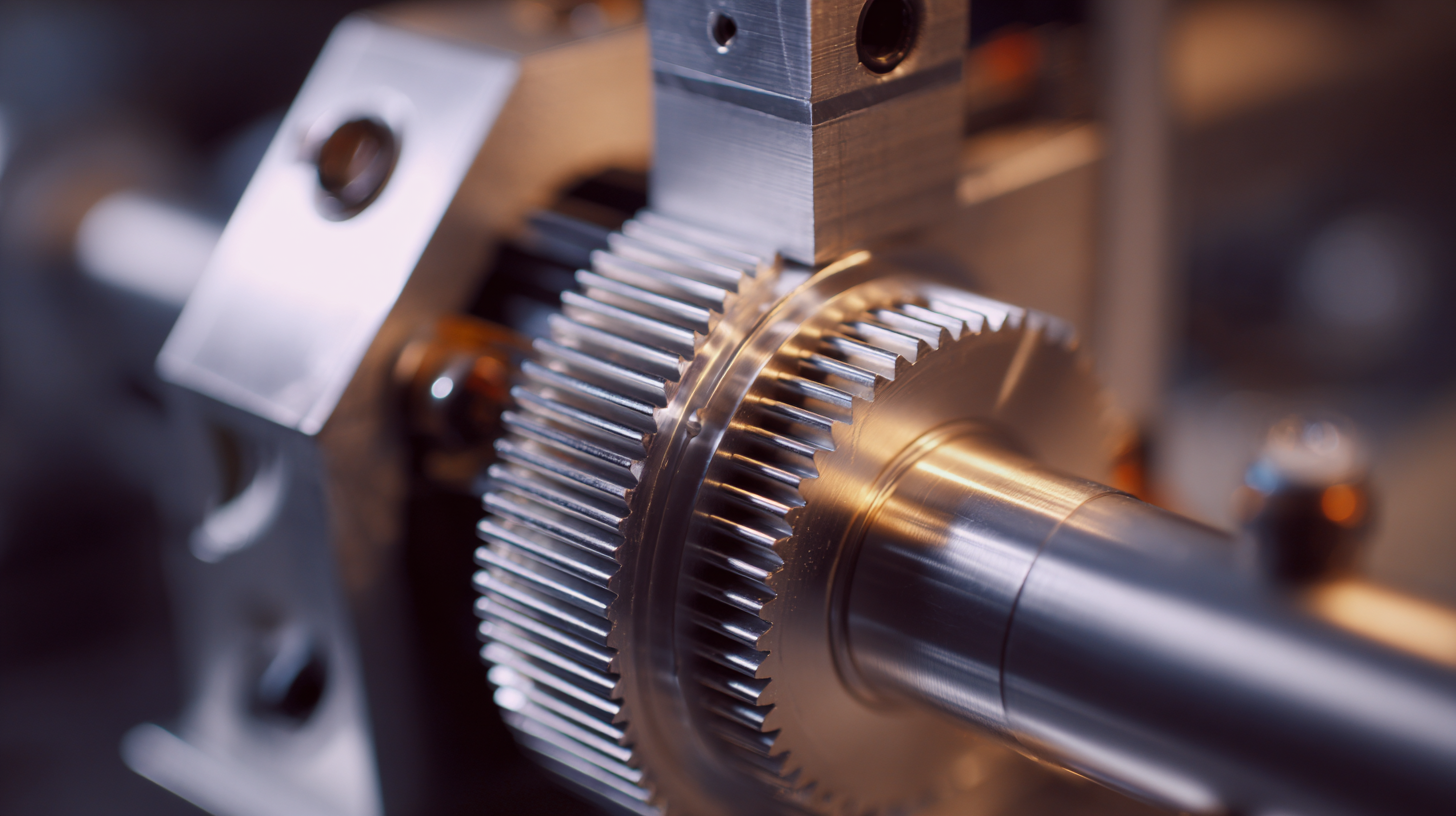

Precision, often associated with the step angle of the motor, is also a defining characteristic of stepper motors. A motor with a smaller step angle provides finer resolution, allowing for more accurate positioning. This is particularly beneficial in applications requiring high levels of detail, such as 3D printing and CNC machining. Understanding how torque, speed, and precision interplay will help identify the most suitable stepper motor for your unique application.

When selecting a stepper motor for your application, evaluating efficiency is crucial. Power consumption not only affects operational costs but also impacts the overall performance of your system. Stepper motors come in various sizes and specifications, and understanding how their power consumption correlates with torque and speed is essential in making an informed choice. A more efficient motor may have a higher upfront cost but can lead to significant savings in the long run.

Tip: Always check the datasheet for a stepper motor's rated current and voltage. Lower current ratings can indicate greater efficiency, but it is important to balance this with the motor's required torque for your application.

Another key consideration is the operating mode of the motor, as this can greatly influence power consumption. Motors often have different operating modes, such as full-step or half-step, which will impact their energy usage. By selecting the appropriate step mode for your application, you can optimize efficiency without sacrificing performance.

Tip: Experimenting with different microstepping modes can help reduce resonant vibration, leading to smoother operation and lower overall power usage. This not only improves performance but also helps in extending the lifespan of the motor.

In the realm of stepper motors, NEMA ratings play a pivotal role in determining the overall performance and reliability of these devices. The National Electrical Manufacturers Association (NEMA) categorizes motors based on their size and frame specifications, which directly correlate with their capabilities in different applications. Understanding these ratings is essential for engineers and designers when selecting the appropriate stepper motor to meet their project's demands.

A higher NEMA rating signifies a larger frame size, typically leading to increased torque output and enhanced heat dissipation. This is crucial in applications requiring precise control and substantial power, such as robotics or CNC machinery. Conversely, smaller NEMA ratings may be suitable for lighter loads and less demanding environments, promoting energy efficiency and compact design. Thus, a comparative analysis of NEMA ratings allows professionals to make informed decisions, ensuring optimal performance and longevity of the stepper motors in various operational conditions.

When selecting stepper motors, the step angle plays a crucial role in achieving optimal resolution and smooth motion. The step angle, typically measured in degrees, dictates how finely the motor can subdivide a full rotation. For instance, a motor with a 1.8-degree step angle can achieve 200 steps per revolution, while a motor with a 0.9-degree step angle offers 400 steps. This finer resolution allows for more precise control of movement, making it ideal for applications requiring high accuracy, such as 3D printing and CNC machining.

To optimize performance, consider the motor's microstepping capabilities. According to industry reports, implementing microstepping can reduce vibration and enhance smoothness in motion. For example, a stepper motor operating in half-step mode can effectively double its resolution to 400 steps per revolution. This results in smoother operation, reduced resonance, and improved overall performance.

Tip: When selecting a stepper motor, always verify its step angle and microstepping compatibility to ensure it meets your application’s requirements. Additionally, remember that while a lower step angle offers better resolution, it may require more complex drive electronics to maintain performance. Therefore, always balance between resolution needs and the complexity of your control system.

China has firmly established itself as a powerhouse in the global stepper motor market, dominating both production and exports. According to a recent report by MarketsandMarkets, the global stepper motor market is projected to reach $8.6 billion by 2025, with China accounting for over 60% of the total supply. This significant market share is largely attributed to the country’s advanced manufacturing capabilities, cost-effective production techniques, and a robust supply chain that supports components and assembly.

The growth in China's stepper motor production is further supported by the rising demand for automation across various industries, including robotics, electronics, and automotive sectors. A study by ResearchAndMarkets highlights that the demand for stepper motors is expected to grow at a CAGR of 5.8% from 2020 to 2027, primarily driven by increasing applications in 3D printing, CNC machinery, and medical devices. As Chinese manufacturers continue to innovate and improve efficiency, their leading position in stepper motor exports is unlikely to diminish, reinforcing the nation's critical role in the global manufacturing landscape.