-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In the rapidly evolving landscape of automation, servo drives have emerged as pivotal components, driving efficiency and precision in various industrial applications. According to a recent report by MarketsandMarkets, the global servo drive market is projected to reach $10.8 billion by 2027, growing at a CAGR of 6.2% from 2022. This growth underscores the significance of servo drives in enhancing machine performance, improving energy efficiency, and enabling advanced motion control. As 2023 unfolds, leading manufacturers are leveraging innovative servo drive technologies to transform automation processes across sectors such as manufacturing, automotive, and robotics. In this blog, we will explore the top five servo drive solutions that are not only redefining operational standards but also propelling the industry towards a more automated future.

The rise of smart servo drives is revolutionizing industrial automation, marking a significant shift in motion control capabilities. With an increasing emphasis on precision, flexibility, and efficiency, industries are turning to advanced servo drive solutions that integrate seamlessly with existing systems. These smart drives not only enhance performance but also enable real-time adjustments, ensuring that operations can respond dynamically to changing conditions. This adaptability is essential for manufacturers aiming to optimize production and reduce costs.

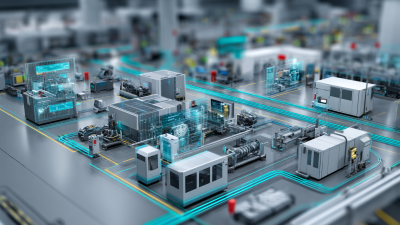

Moreover, the global variable frequency drive market is undergoing rapid growth, projected to reach $32.00 billion by 2025. This surge reflects a broader trend toward intelligent automation, where the ability to predict and maintain equipment health is paramount. AI-based predictive maintenance is emerging as a key strategy to increase robot availability, significantly mitigating the costs of unplanned downtime, which for industrial manufacturers can exceed €45 billion annually. As companies invest in robotics and smart technologies, the future of manufacturing looks poised for a transformation that prioritizes smart solutions for sustainable growth.

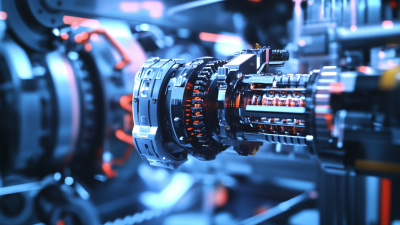

In 2023, advanced servo technologies have become pivotal in maximizing precision and efficiency across various sectors, transforming automation practices. The integration of digital and physical systems is at the core of this advancement, fostering the development of sophisticated mechatronic solutions. For instance, the global motion control market is projected to grow from $16.5 billion in 2024 to an impressive $21.6 billion by 2032. This growth underscores the increasing reliance on automation technologies for enhanced productivity.

One striking example is found in precision motion control systems, which have revolutionized industries such as semiconductor manufacturing. These systems utilize AI and advanced algorithms to ensure remarkable accuracy, directly contributing to innovation and efficiency. Additionally, advancements in robotics are significantly improving agricultural practices, matching rising global food demands with reliable automation. By leveraging advanced technologies, the agricultural sector can mitigate crop losses, thus ensuring sustainable food production.

Tips: When implementing advanced servo technologies, ensure comprehensive training for operators to maximize system utilization. Regular maintenance of automation systems is crucial for maintaining high performance and avoiding costly downtimes. Lastly, routinely evaluate the return on investment from automation upgrades to ensure alignment with overall business goals.

As industries increasingly focus on sustainability, servo drives play a pivotal role in transforming manufacturing practices toward more eco-friendly solutions. These advanced systems optimize energy consumption by precisely controlling motor speeds and torque, thereby reducing waste and ensuring that resources are used efficiently. With capabilities such as regenerative braking, servo drives not only minimize energy loss but also contribute to lowering the overall carbon footprint of production processes.

Moreover, the integration of servo drives into automated systems enhances product quality while reducing material waste. By improving precision during manufacturing, businesses can achieve tighter tolerances and better control over processes, which leads to fewer defects and reworks. This efficiency, combined with the adaptability of servo drives to various applications, positions them as essential tools in the shift towards greener manufacturing. As companies continue to adopt these technologies, the potential for sustainable practices in automation becomes increasingly apparent, showcasing the importance of innovation in achieving environmental goals.

As we navigate through 2023, the integration of AI in servo drive solutions is rapidly transforming automation frameworks across various industries. By utilizing data-driven insights, companies can harness predictive maintenance capabilities that significantly enhance operational efficiency. According to a recent report from the International Data Corporation (IDC), predictive maintenance powered by AI can reduce maintenance costs by up to 30% while increasing equipment uptime by approximately 20%. This shift not only optimizes performance but also extends the lifespan of machinery, leading to substantial long-term savings.

Furthermore, the use of AI algorithms in analyzing real-time data allows manufacturers to anticipate equipment failures before they happen. A study from McKinsey & Company highlights that organizations implementing advanced analytics in their maintenance processes can improve their productivity by 10 to 15%. This proactive approach minimizes unexpected downtimes and ensures a smoother operational flow. As servo drive technology continues to evolve, leveraging AI for predictive insights will be crucial in achieving a competitive edge in the automation landscape.

The integration of modern servo drive systems in automation processes has shown significant potential in enhancing operational efficiency and reducing costs. According to a recent report by ResearchAndMarkets, the global servo drive market is projected to reach $12.9 billion by 2027, growing at a CAGR of 5.8%. This growth is largely driven by the increasing demand for automation in manufacturing sectors, where servo drives offer precise motion control and energy efficiency. A cost-benefit analysis reveals that businesses can expect a return on investment (ROI) within 1-2 years after implementing these advanced systems, with potential savings of up to 20% in energy consumption alone.

When evaluating the ROI of servo drive systems, it’s crucial to consider both direct and indirect financial benefits. A whitepaper published by Siemens highlights that companies utilizing modern servo technology can experience a 30% reduction in cycle times and a significant decrease in maintenance costs, thanks to their robust design and reliability. Furthermore, the reduction in downtime associated with improved motion control often leads to enhanced productivity, contributing to overall profit margins. As industries increasingly transition towards sustainable and efficient production methods, the adoption of cutting-edge servo drive solutions stands out as a strategic investment for optimizing automation in 2023.

| Servo Drive Solution | Key Features | Cost ($) | ROI (%) | Payback Period (Years) |

|---|---|---|---|---|

| Solution A | High Precision, Low Latency | 1500 | 25 | 3 |

| Solution B | Compact Design, Energy Efficient | 2000 | 30 | 2.5 |

| Solution C | User-Friendly Interface, Modular | 1800 | 28 | 2.8 |

| Solution D | Advanced Diagnostics, High Torque | 2200 | 35 | 2 |

| Solution E | Cost-effective, Scalable | 1600 | 27 | 3.5 |