-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In the ever-evolving landscape of industrial automation, the quest for enhanced performance and efficiency has led to significant advancements in technology, notably in the realm of Servo Drives. These sophisticated controllers play a pivotal role in managing motion systems, providing precise control over position, speed, and torque in various applications. As industries strive to optimize their operations, the demand for reliable, high-performing Servo Drives has surged, prompting manufacturers to innovate and develop solutions that meet the diverse needs of modern production environments.

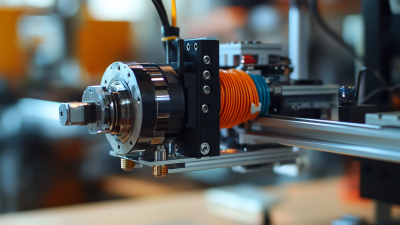

Servo Drives are integral to the operation of servo motors, translating commands from controllers into actionable movement. Their ability to deliver accurate and responsive performance makes them essential in numerous fields, from robotics to packaging, where precision and reliability are paramount. The right Servo Drive can significantly enhance machinery capabilities, leading to improved productivity and reduced downtime. In this article, we will explore the top 10 Servo Drives that stand out for their performance features, ease of integration, and adaptability to different industrial applications, empowering businesses to elevate their operational efficiency to new heights.

In the realm of industrial automation, servo drives play a pivotal role in enhancing the efficiency and precision of various applications. These drives convert electrical energy into mechanical motion, allowing for precise control of position, speed, and torque in machinery such as robotics, CNC machines, and conveyor systems. As per a report from the International Federation of Robotics, the adoption of advanced automation technologies, including servo drives, has increased productivity across manufacturing sectors by up to 20% annually.

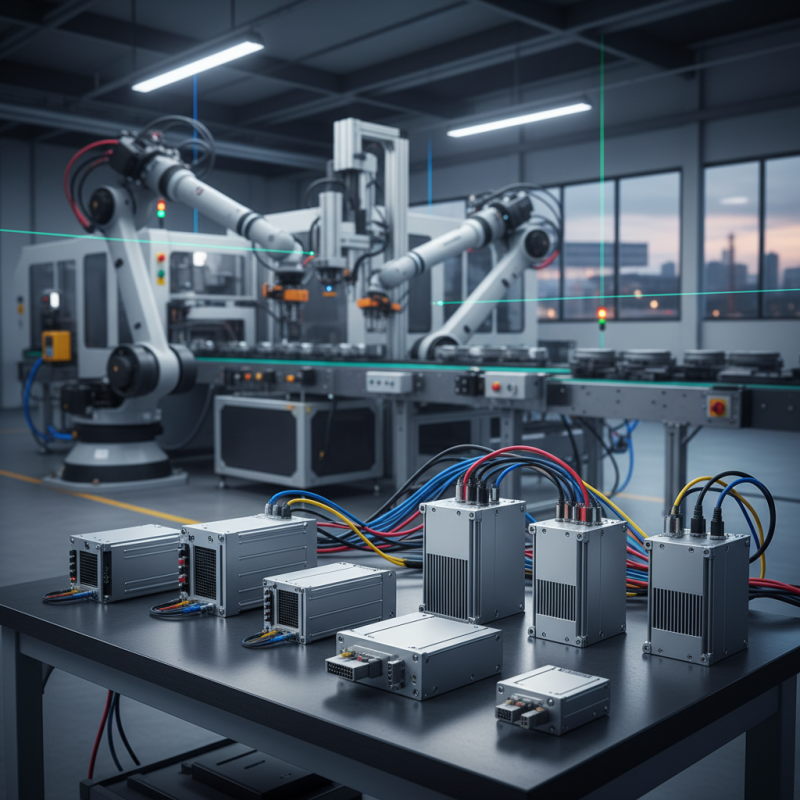

As industries continue to evolve, the integration of smart technologies and IoT capabilities into servo drives has become crucial. Modern servo drives are not only designed for optimal performance but also for connectivity and data analysis, allowing manufacturers to monitor and adjust operations in real-time. A recent study indicates that facilities utilizing smart servo drives can achieve operational efficiency improvements by 30% through reduced downtime and enhanced predictive maintenance.

Tips: When selecting a servo drive, consider the specific requirements of your application, including load characteristics and required response times. Additionally, integrating your servo drive with a comprehensive automation system can significantly boost overall productivity and operational insights, leading to smarter manufacturing processes.

| Model | Rated Current (A) | Voltage Rating (V) | Communication Protocol | Control Type | Key Features |

|---|---|---|---|---|---|

| Model A | 20 | 400 | CANopen | Position Control | High efficiency, compact design |

| Model B | 15 | 230 | EtherCAT | Torque Control | Integrated safety features |

| Model C | 30 | 480 | Modbus RTU | Velocity Control | User-friendly interface, real-time diagnostics |

| Model D | 25 | 500 | Profibus | Position Control | Sensorless torque control, flexible configuration |

| Model E | 10 | 220 | Serial Communication | Current Control | Compact size, affordable |

| Model F | 50 | 600 | Ethernet/IP | Position and Velocity Control | Advanced control algorithms, high power density |

| Model G | 40 | 480 | CANopen | Torque Control | High torque stability, robust design |

| Model H | 35 | 360 | RS-485 | Speed Control | Easy configuration, stable output |

| Model I | 22 | 240 | EtherCAT | Position Control | Support for multi-axis control |

| Model J | 12 | 220 | CANopen | Torque Control | Low latency control, compact |

High-performance servo drives play a crucial role in enhancing the operational efficiency of industrial applications. These drives offer advanced control techniques that allow for precise positioning and motion control, which are essential for automated systems and robotics. According to a report by MarketsandMarkets, the servo drives market is expected to grow from USD 10.3 billion in 2021 to USD 16.0 billion by 2026, highlighting a compound annual growth rate (CAGR) of 9.3%. This growth is driven by the increasing demand for energy-efficient systems and the rising adoption of automation in manufacturing processes.

One of the key features of high-performance servo drives is their ability to reduce energy consumption while improving overall system performance. Many modern servo drives incorporate regenerative braking technology, which recycles energy back into the system during deceleration, leading to significant energy savings. Additionally, the integration of advanced feedback mechanisms enables real-time adjustments, resulting in enhanced accuracy and reduced cycle times.

A study published in the Journal of Manufacturing Science and Engineering noted that optimizing servo drive performance can lead to productivity improvements of up to 30%, underlining the importance of these devices in competitive manufacturing environments. As industries continue to seek out innovative solutions to improve efficiency and productivity, high-performance servo drives will remain critical components in the evolution of industrial automation.

When selecting a servo drive for your industrial application, there are several critical considerations to ensure optimal performance. The first factor to consider is the compatibility with your motor type. Different servo drives are designed to work with specific motor technologies, such as AC or DC motors. Ensuring that your chosen drive matches the motor's specifications is vital for achieving efficient operation and avoiding potential damage.

Another essential aspect is the drive's control mode. Servo drives come with various control options, such as position, speed, and torque control. Evaluate the specific needs of your application to determine which mode will best suit your performance requirements. Additionally, consider the communication protocols supported by the drive. Compatibility with your existing system's communication standards will facilitate seamless integration and enhance overall functionality.

Tips: Always look for a drive that allows for easy tuning and configuration. This flexibility can significantly reduce setup time and enhance performance optimization. Additionally, exploring options for built-in safety features can safeguard both your equipment and personnel, making it a wise investment in long-term operational reliability. Don’t forget to examine the scalability of the servo drive for future applications, ensuring that it can adapt as your industrial needs evolve.

In the competitive landscape of industrial automation, servo drives are crucial for achieving precision and efficiency in various applications. A comparative analysis of the leading servo drive brands reveals distinct strengths and weaknesses that can significantly influence performance outcomes. Manufacturers invest heavily in technology that enhances

control, responsiveness, and integration capabilities. Ultimately, this results in varying degrees of performance metrics, such as speed, torque response, and energy efficiency.

One of the key factors differentiating these servo drives is the optimization of control algorithms. Some brands focus on advanced features like adaptive control, which allows servo systems to learn and adjust in real-time to changing operational conditions. Others may prioritize ease of integration with existing systems, ensuring that their drives can be quickly deployed without significant adjustments to existing hardware or software. Additionally, the robustness of the drive in different environments—such as temperature fluctuations, vibration, and dust exposure—plays a critical role in determining suitability for specific applications. By understanding these factors, industries can make informed decisions to enhance their operational efficiencies effectively.

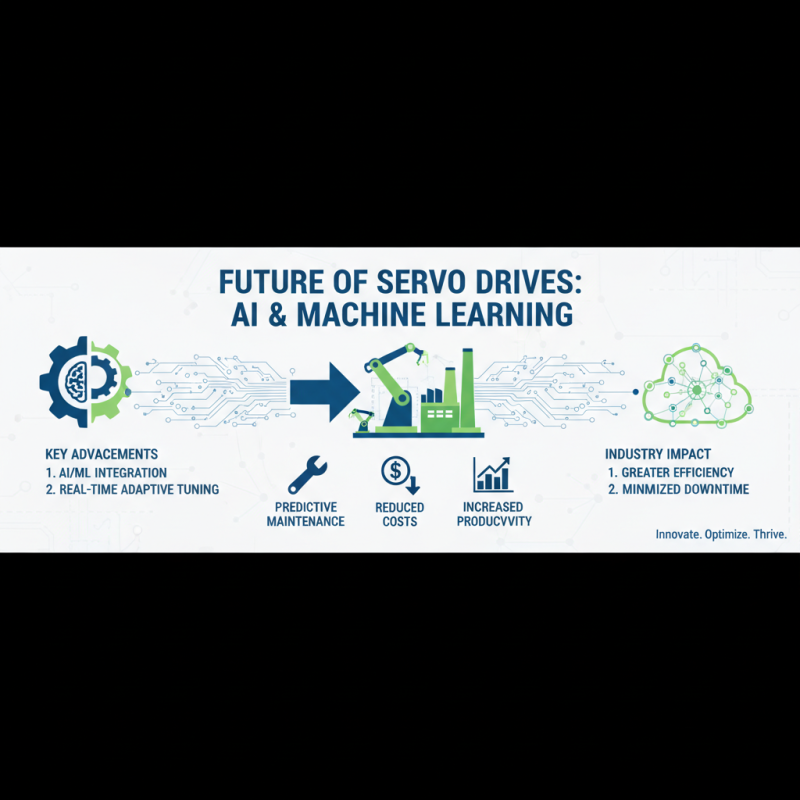

The future trends in servo drive technology for industrial applications are poised to revolutionize the way industries operate. One of the most significant advancements is the integration of artificial intelligence and machine learning into servo drive systems. This integration allows for real-time data analysis and adaptive performance tuning, enabling machines to optimize their processes dynamically. As industries strive for greater efficiency and reduced downtime, AI-powered servo drives will facilitate predictive maintenance, reducing operational costs and increasing overall productivity.

Additionally, the rise of Industry 4.0 is shifting the focus towards enhanced connectivity and interoperability among devices. Servo drives are expected to incorporate advanced communication protocols that allow them to work seamlessly with other automation systems and IoT devices. This connectivity will enable manufacturers to gain deeper insights into their operations through improved data collection and analysis, fostering a more agile and responsive manufacturing environment. As these trends unfold, industries will benefit from increased automation capabilities, leading to a more streamlined production process.