-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

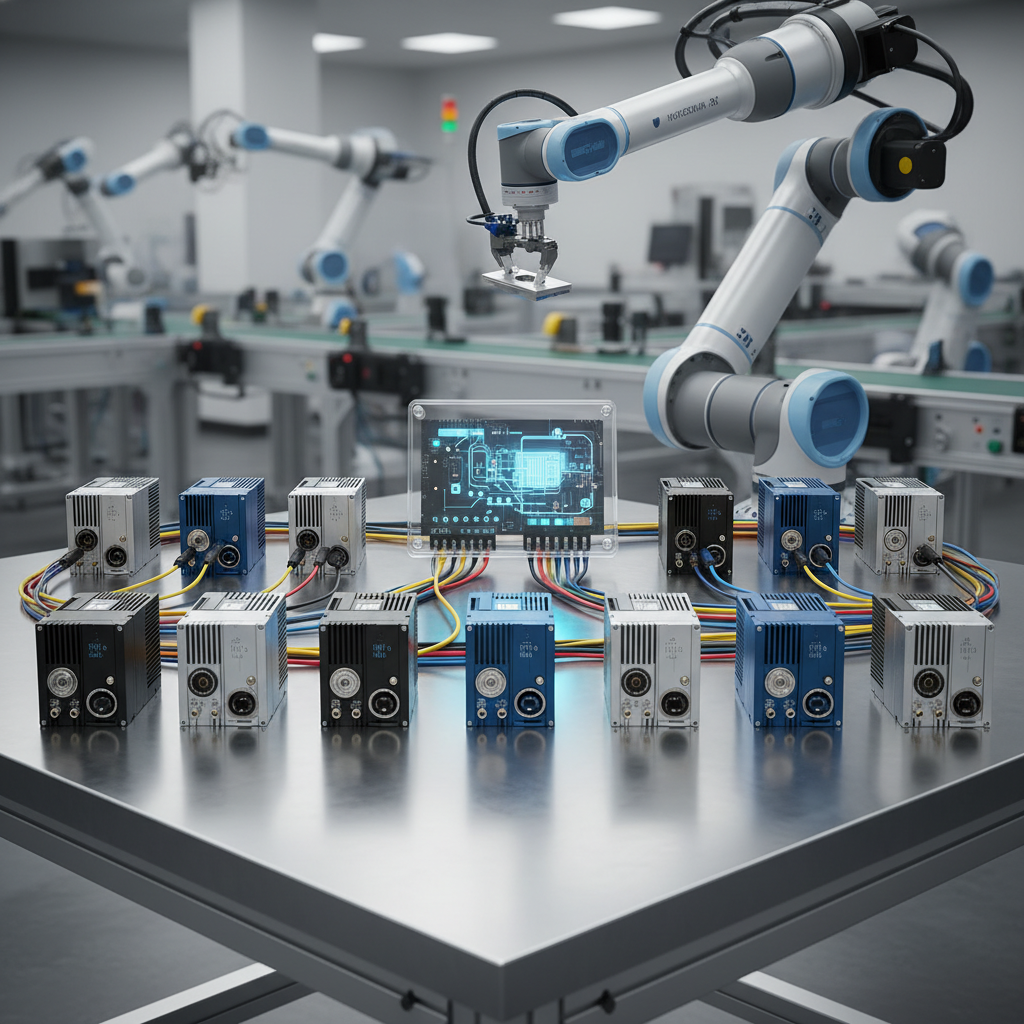

In the realm of industrial automation, precision and control are paramount for enhancing productivity and efficiency. One of the key components that enable such high levels of accuracy is the Servo Motor Drive. These sophisticated devices are designed to manage the movement of servo motors with exceptional precision, making them indispensable across various applications, from manufacturing to robotics. With the rapid advancement of technology, businesses are increasingly relying on state-of-the-art servo motor drives to ensure that their operations remain competitive and precise.

This article delves into the top 10 servo motor drives that stand out in the market today, offering invaluable insights into their features, benefits, and ideal use cases. By exploring these innovative solutions, industry professionals can make informed decisions that align with their automation needs. Whether you are looking to improve the accuracy of your machining processes, enhance the responsiveness of your robotic systems, or streamline production lines, understanding the capabilities of the best servo motor drives is essential. Join us as we navigate through these cutting-edge technologies that promise to elevate precision control in the ever-evolving landscape of industrial automation.

Servo motor drives play a pivotal role in precision control within industrial automation systems. By providing accurate positioning, speed regulation, and torque control, these drives ensure that machinery operates with the utmost efficiency and reliability. The integration of advanced algorithms and feedback mechanisms enables servo drives to maintain performance even under varying load conditions, thereby minimizing errors during production processes. This capability is essential for applications that demand high precision, such as CNC machining, robotics, and packaging systems.

The effectiveness of servo motor drives is further enhanced by their adaptability to different industrial environments. With the ability to interface with various sensors and controllers, these drives can be customized to meet the specific requirements of diverse applications. Moreover, innovations in technology, such as digital communication protocols and enhanced energy efficiency, have expanded the functionalities of servo drives, making them indispensable in modern automated systems. As industries continue to evolve, the reliance on servo motor drives for precision control and improved productivity will only grow.

When selecting high-performance servo motor drives for precision control in industrial automation, several key features should be prioritized. Firstly, the accuracy of the position control system is crucial. Reports indicate that advanced servo drives can achieve positioning accuracy within 0.01mm, ensuring that even the most delicate operations are executed flawlessly. Additionally, the response speed of the drive plays a vital role in maintaining productivity; modern servo drives can accelerate to their operational speed in less than 20 milliseconds, significantly enhancing operational efficiency.

Another important feature to consider is the integration capability with existing systems. Drives that offer seamless communication protocols, such as EtherCAT or CANopen, enable better integration with programmable logic controllers (PLCs) and other industrial systems, thus streamlining operations. According to the 2023 Industry Research Report, companies that invest in servo drives with advanced connectivity options experienced a 15% increase in overall system performance.

**Tips:** Always evaluate the thermal performance of servo drives. Drives with superior heat dissipation mechanisms can operate reliably in demanding industrial environments, thus extending their lifespan. It's also beneficial to look for drive diagnostics features, which allow for real-time monitoring and troubleshooting, helping to reduce downtime and maintenance costs.

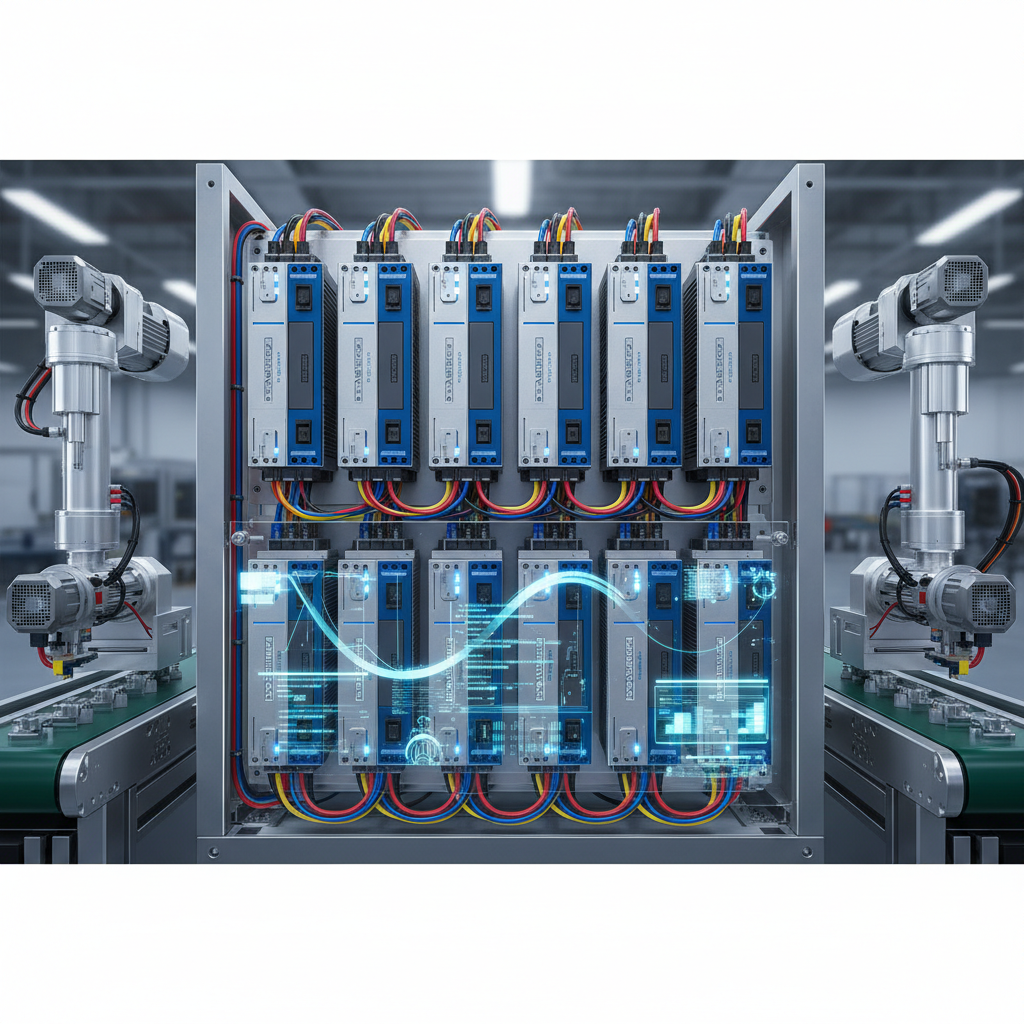

This chart illustrates the key features to look for in high-performance servo motor drives, comparing torque, speed, and precision ratings.

When selecting servo motor drives for industrial automation, it is crucial to consider the specifications that define their performance and suitability for demanding applications. Key factors such as torque, speed, and response time play significant roles in evaluating each drive. For instance, drives with higher torque ratings can better handle load variations, while those with faster response times ensure precise control during dynamic operations. Analyzing these specifications allows engineers to choose drives that seamlessly integrate into existing systems and meet the specific needs of their applications.

Moreover, performance comparisons among different servo motor drives reveal notable differences in energy efficiency and reliability. Drives that utilize advanced digital signal processing often exhibit superior performance, reducing energy consumption while maximizing output. By examining parameters like thermal performance and built-in safety features, users can make informed decisions that enhance the longevity and efficiency of their automation processes. Ultimately, a thorough understanding of these specifications and performance metrics will lead to optimized automation solutions tailored to the unique challenges faced in industrial environments.

| Model | Max Output Power (kW) | Control Type | Communication Protocol | Feedback Type | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 5 | Position | EtherCAT | Absolute Encoder | 2.5 |

| Model B | 7.5 | Torque | CANopen | Incremental Encoder | 3.0 |

| Model C | 10 | Velocity | PROFIBUS | Absolute Encoder | 4.0 |

| Model D | 15 | Position | EtherNet/IP | Incremental Encoder | 5.0 |

| Model E | 20 | Torque | Modbus | Absolute Encoder | 6.5 |

| Model F | 25 | Velocity | CC-Link | Incremental Encoder | 8.0 |

| Model G | 30 | Position | EtherCAT | Absolute Encoder | 9.0 |

| Model H | 40 | Torque | CANopen | Incremental Encoder | 11.0 |

| Model I | 50 | Velocity | PROFIBUS | Absolute Encoder | 12.5 |

| Model J | 60 | Position | EtherNet/IP | Incremental Encoder | 15.0 |

Servo motor drives play a crucial role in enhancing automation precision across various industrial applications. By enabling accurate control of motor position, velocity, and torque, these drives ensure that machinery operates smoothly and efficiently. In sectors such as manufacturing, robotics, and packaging, servo motor drives are integral in achieving high levels of precision, leading to improved product quality and reduced material waste. The advanced feedback mechanisms used in modern servo systems allow them to make real-time adjustments, adapting to any changes in load conditions, which is vital for operations demanding tight tolerances.

In the automotive industry, for instance, servo motor drives are utilized for assembly line automation, where precision movements are essential for tasks like welding and painting. Their ability to offer consistent performance over extended periods minimizes downtime and ensures that production meets rigorous quality standards. Similarly, in the semiconductor manufacturing sector, servo motors are essential for the exact placement of components, where even the slightest deviation can lead to significant defects. As industries continue to evolve towards automation, the adoption of servo motor drives represents a step forward in enhancing operational precision and overall efficiency.

The integration of servo motor drives in industrial automation systems not only enhances precision control but also significantly contributes to energy efficiency. These advanced drives allow for fine-tuned motion control, enabling machines to operate at optimal speeds while reducing energy waste. By implementing closed-loop control systems, servo drives can adjust power output dynamically, matching the exact requirements of the load at any given moment. This capability minimizes excess energy consumption, translating into lower operating costs and a reduced carbon footprint.

Moreover, the evolution of servo motor technologies has led to the development of high-efficiency drives that employ advanced algorithms and real-time monitoring. These features facilitate predictive maintenance, allowing for timely interventions that can prevent energy losses. As industries increasingly prioritize sustainability, the role of energy-efficient servo motor drives becomes paramount. Companies investing in these technologies not only bolster their operational performance but also align with global energy conservation initiatives, promoting a greener future in industrial automation.