-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

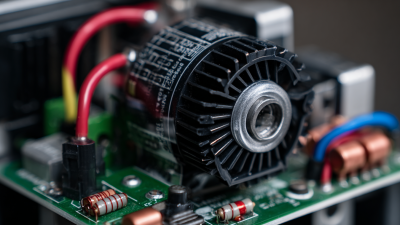

In the realm of modern automation and precision engineering, stepper motor controllers play a crucial role in driving the performance and efficiency of various applications. As technology advances, the need for reliable and versatile stepper motor controller solutions becomes increasingly vital for engineers and developers. Whether for robotics, CNC machinery, or 3D printing, the ability to accurately control stepper motors is essential for achieving optimal operation and functionality.

This article delves into the top stepper motor controller solutions available in 2025, highlighting their key features, advantages, and the specific applications they are best suited for. By exploring these innovative controllers, we aim to provide insights that assist in selecting the most appropriate solution tailored to individual project requirements. As the landscape of stepper motor technology continues to evolve, understanding these solutions will empower developers to enhance performance and ensure the success of their applications.

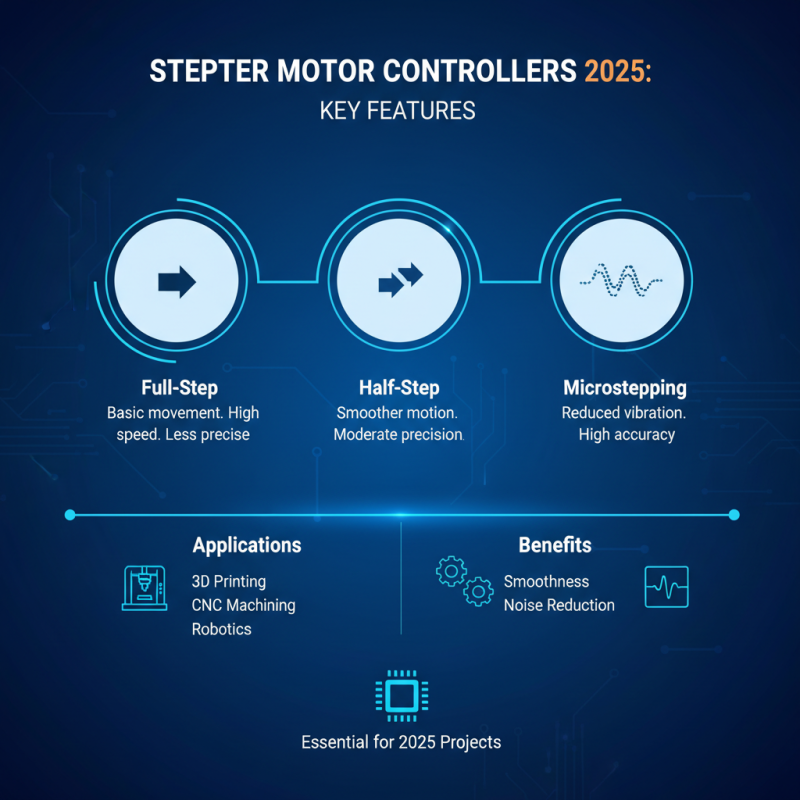

When considering the ideal stepper motor controller for your projects in 2025, it's imperative to understand the core features that different controllers bring to the table. Leading controllers typically offer modes of operation such as full-step, half-step, and microstepping, each providing varying degrees of precision and smoothness in motor movement. Microstepping, in particular, allows for finer control and reduces vibration, making it essential for applications requiring high accuracy, such as in 3D printing and CNC machining.

Another critical feature to look for is the ease of integration with existing systems. Many modern controllers come equipped with communication protocols such as UART, I2C, or CAN, simplifying connections to microcontrollers and other devices. Additionally, advanced controllers offer programmability, enabling users to tailor specific torque and speed profiles to their needs, enhancing overall system performance.

Tips: Always assess the thermal management capabilities of a stepper motor controller, as overheating can lead to failure and underperformance. Ensure that you also evaluate the size and footprint of the controller, especially if space constraints are a concern in your project. Choosing a controller that balances performance with heat dissipation can save you from potential pitfalls in your design.

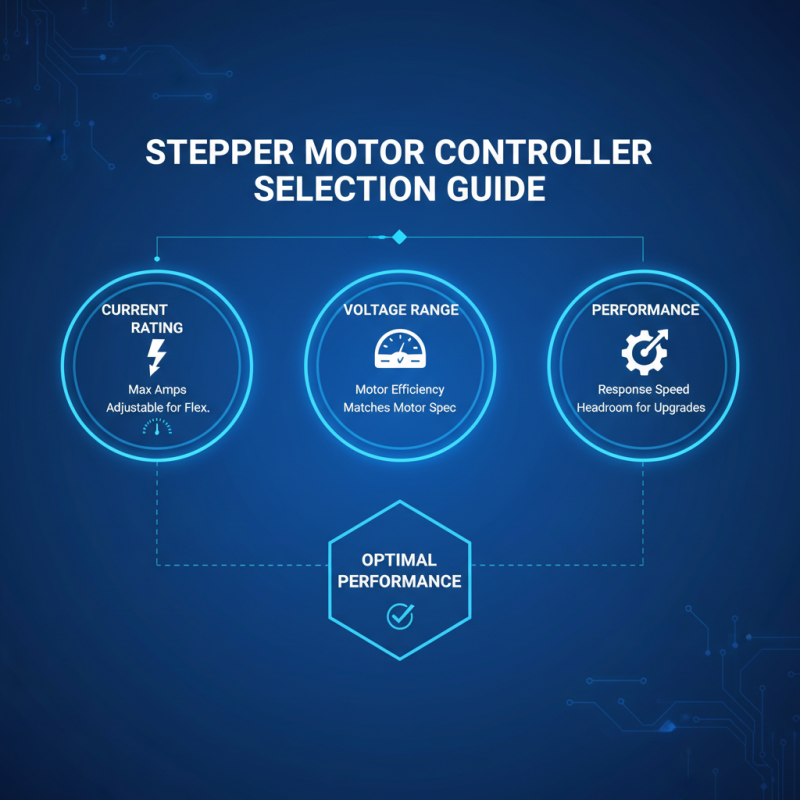

When selecting a stepper motor controller for your projects and applications, there are several key specifications that must be taken into account to ensure optimal performance. Firstly, the current rating is critical, as it determines the maximum current that the motor can handle. A controller with adjustable current settings can offer flexibility in adapting to different motor types and loads, making it essential for various applications. Additionally, the voltage range supported by the controller impacts the efficiency and response speed of the motor, so it's important to choose one that aligns with your motor specifications while providing headroom for performance enhancements.

Another vital specification to consider is the stepping resolution, which affects the precision of the motor’s movements. Controllers that offer microstepping capabilities allow for smoother operation and finer control, making them especially beneficial in applications requiring high accuracy. Moreover, the interface compatibility of the controller is crucial; it should be able to communicate effectively with your existing system, whether it utilizes UART, I2C, or other communication protocols. By focusing on these key specifications, you can select a stepper motor controller that not only fulfills your immediate project needs but also offers scalability for future applications.

When evaluating the leading stepper motor controller brands, it is essential to consider several factors that can significantly impact the performance and efficiency of your projects. Among the key aspects are the controller's compatibility with various stepper motor types, the precision of control offered, and the ease of integration with existing systems. High-quality controllers tend to provide advanced microstepping capabilities, which enhance the smoothness and accuracy of motor movements, crucial for applications requiring fine control.

Furthermore, the support and resources available from manufacturers play a vital role in the selection process. Brands that offer comprehensive documentation, user-friendly interfaces, and responsive customer support can greatly reduce development time and ensure successful implementation. Reliability and durability are also pivotal; a robust controller will not only perform well under various conditions but also extend the lifespan of your overall system. By focusing on these comparative features, projects can benefit from optimized performance and adaptability across different applications.

The evolution of stepper motor controllers is significantly shaping the future of automation across various sectors. According to a recent industry report by Research and Markets, the global stepper motor controller market is projected to reach $1.2 billion by 2025, growing at a CAGR of 6.1% from 2020 to 2025. This growth is driven by the increasing automation demand in industries such as manufacturing, robotics, and automotive, where precision and control are paramount.

One of the key trends in the market is the integration of advanced technologies such as IoT and AI in stepper motor controllers. This integration enhances the ability of these controllers to communicate with other devices and systems, leading to more efficient operations. Furthermore, the push towards energy efficiency and sustainability in manufacturing processes is prompting manufacturers to adopt more sophisticated and intelligent stepper motor solutions. According to a survey by Technavio, about 25% of companies are looking to invest in smart motion control systems by 2025.

Stepper motor controllers have gained unprecedented popularity in various applications due to their precision and reliability. According to a recent report by MarketsandMarkets, the global stepper motor market is expected to reach $6.25 billion by 2025, showcasing a significant compound annual growth rate (CAGR) of 4.3% from 2020 to 2025. This growth is driven by the increasing demand for automation in industries such as manufacturing, robotics, and consumer electronics. Case studies highlight successful implementations of stepper motor controllers in automated assembly lines, where they have been instrumental in enhancing production efficiency and reducing operational costs. For instance, a medical device manufacturer reported a 30% increase in output after integrating stepper motor technology into their assembly process.

In addition to manufacturing, stepper motor controllers are also making waves in the 3D printing industry. The technology relies heavily on precise motor control to ensure accurate layer placement, which is critical for producing high-quality prints. A study published in the International Journal of Advanced Manufacturing Technology revealed that companies utilizing advanced stepper motor controllers in their 3D printers achieved a reduction in print time by up to 25% while maintaining superior dimensional accuracy. This showcases how the adoption of stepper motor solutions can not only bolster efficiency but also enhance product quality across diverse applications.

This chart illustrates the performance of various stepper motor controller solutions across different applications. The data represents various applications and their corresponding control efficiency ratings based on case studies conducted in 2025.