-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In today's rapidly advancing industrial landscape, the demand for precision and efficiency has never been higher, making Servo Motors a crucial component in various applications from robotics to aerospace. According to a recent industry report by ResearchAndMarkets, the global servo motor market is projected to reach $9.89 billion by 2025, growing at a CAGR of 6.14%. This growth is fueled by the increasing adoption of automation in manufacturing processes, where the need for accurate motion control is paramount.

Selecting the right servo motor involves understanding a range of technical specifications—from torque and speed to feedback systems and control methods. This comprehensive guide aims to unlock the intricacies of servo motors, offering insights that empower engineers and decision-makers to choose the best solutions for their projects, thereby driving innovation and productivity in their respective fields.

Servo motors are integral components in numerous applications, providing precise control of angular or linear position, velocity, and acceleration. Understanding the basics of servo motors begins with key definitions. A servo motor is essentially a closed-loop system that uses feedback to maintain the desired position, allowing for unmatched accuracy in movement. This contrasts with traditional motors, which operate on an open-loop system without such feedback mechanisms.

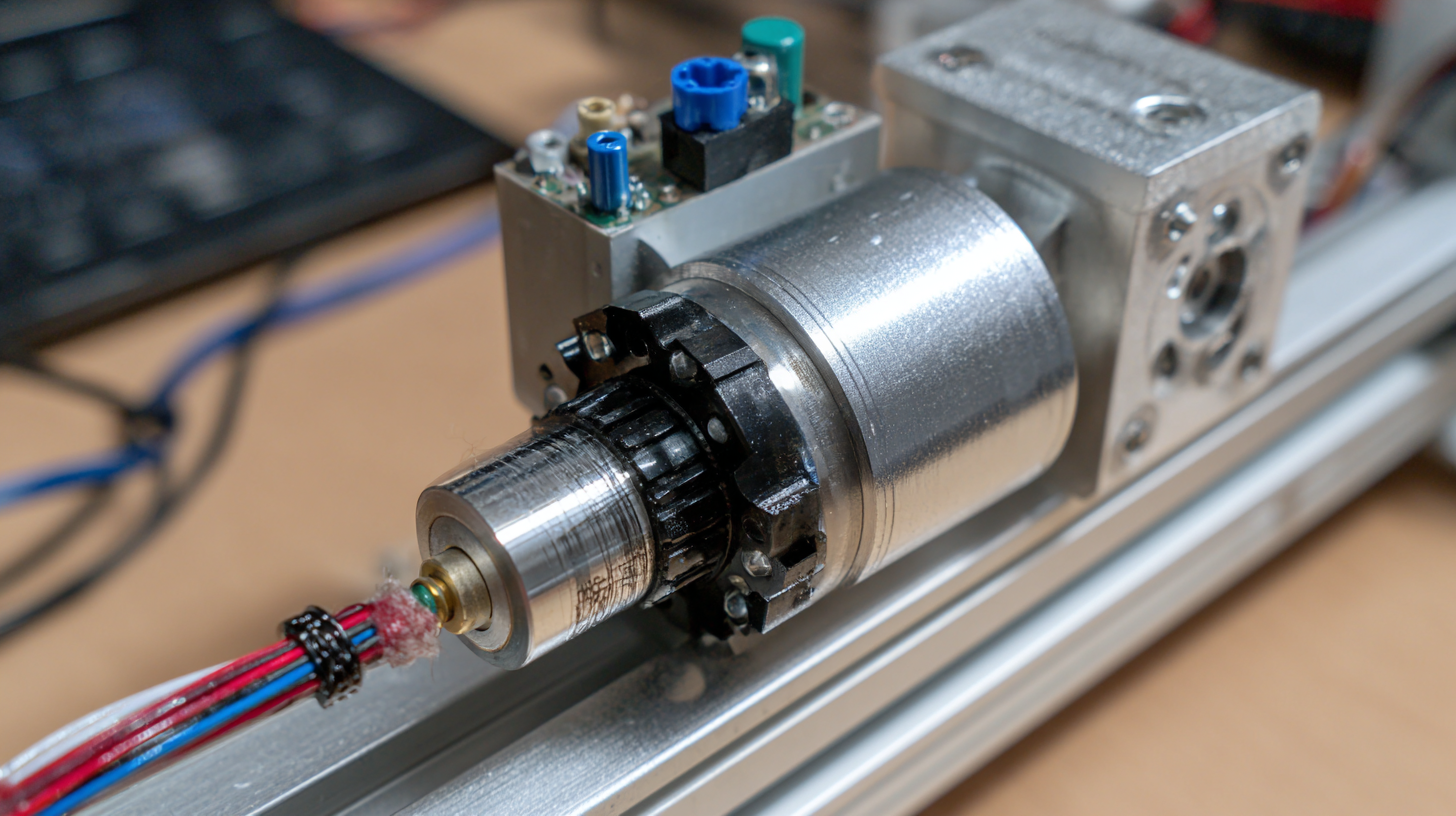

At its core, a servo motor consists of a motor coupled to a sensor, which provides real-time data on the motor's position. This interplay between the motor and the sensor enables the system to make necessary adjustments instantaneously, ensuring precise control. Common types of servo motors include AC servo motors, DC servo motors, and stepper motors, each serving different applications but sharing the common trait of enhanced control and responsiveness.

Understanding these fundamental concepts is crucial for selecting the right servo motor, as the correct specifications can significantly impact performance in automation, robotics, and manufacturing processes.

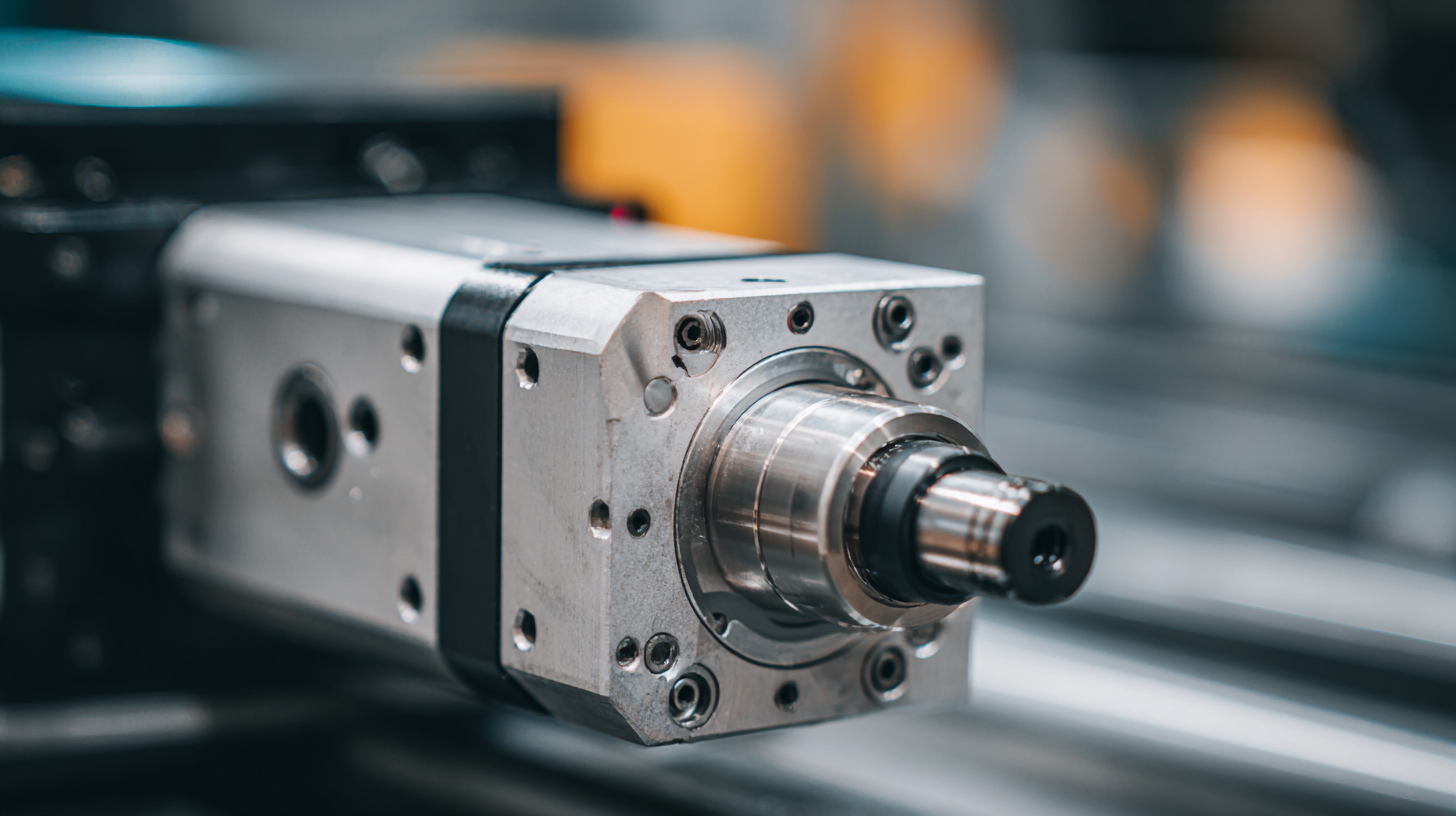

When selecting a servo motor, understanding the essential technical specifications is crucial for achieving optimal performance in various applications. Key specifications to look for include the type of motor—AC or DC—each offering unique advantages depending on the use case. For instance, AC servo motors typically provide greater torque and efficiency for high-speed operations, while DC motors are preferred for their simpler control and ease of integration in smaller applications.

Another critical specification is the voltage classification of the servo motor. Motors are generally categorized into low, medium, and high voltage, and the choice should align with the power requirements of the project. Low voltage motors are ideal for lightweight and portable devices, while medium and high voltage motors can handle larger loads, making them suitable for industrial applications.

**Tips:**

1. Always consider the end-user application when selecting servo motors, as different industries may have varying demands for precision and responsiveness.

2. Look for comprehensive documentation of technical specifications from manufacturers to ensure compatibility and performance meet your project requirements.

| Specification | Value |

|---|---|

| Torque Rating | 0.5 - 30 Nm |

| Speed | 1000 - 6000 RPM |

| Voltage | 12 - 48 VDC |

| Feedback Type | Incremental Encoder / Absolute Encoder |

| Control Type | PWM / Analog |

| Protection Rating | IP65 |

| Weight | 2 - 10 kg |

| Operating Temperature | -20°C to +70°C |

In today's robotics industry, understanding the technical specifications of servo motors is crucial for optimizing performance in various applications. One of the key performance metrics that engineers evaluate is torque. For instance, the recent launch of a new integrated robotic joint module has showcased an impressive peak torque of 120Nm, with a torque constant reaching 2.5Nm/A. These numbers highlight the importance of selecting servo motors that not only provide adequate torque but also maintain efficiency across operational ranges.

Speed is another critical factor in evaluating servo motor performance. The response time and acceleration capabilities directly impact how quickly a robotic system can perform tasks, affecting overall productivity. According to industry reports, high-performance servo motors can achieve rapid accelerations and decelerations, often measured in degrees per second, enabling systems to handle dynamic applications effectively. As engineers continue to push the boundaries of robotics, precision becomes an indispensable requirement; thus, finding motors with low backlash and high resolution is essential in minimizing positional errors and enhancing reliability in operational tasks.

Additionally, precision specifications play a significant role in how servo motors contribute to automation. The integration of advanced feedback systems in motors can significantly improve cycle times and task accuracy, leading to a more streamlined workflow. Current trends suggest that manufacturers are focusing on providing enhanced precision metrics, ensuring that their products not only meet but exceed industry standards for performance and reliability.

Choosing the right type of servo motor for your application is crucial in achieving optimal performance and efficiency. Servo motors come in various types, including AC, DC, and stepper motors, each offering unique advantages depending on the specific needs of your project. For applications requiring high precision and speed, AC servo motors are often the best choice due to their ability to maintain performance under varying load conditions. On the other hand, if your project demands more straightforward control and lower costs, DC servo motors may be the ideal solution.

**Tip:** Always assess the torque and speed requirements of your application before making a decision. Calculate the necessary parameters to ensure that the selected servo motor can handle the specific demands of your system.

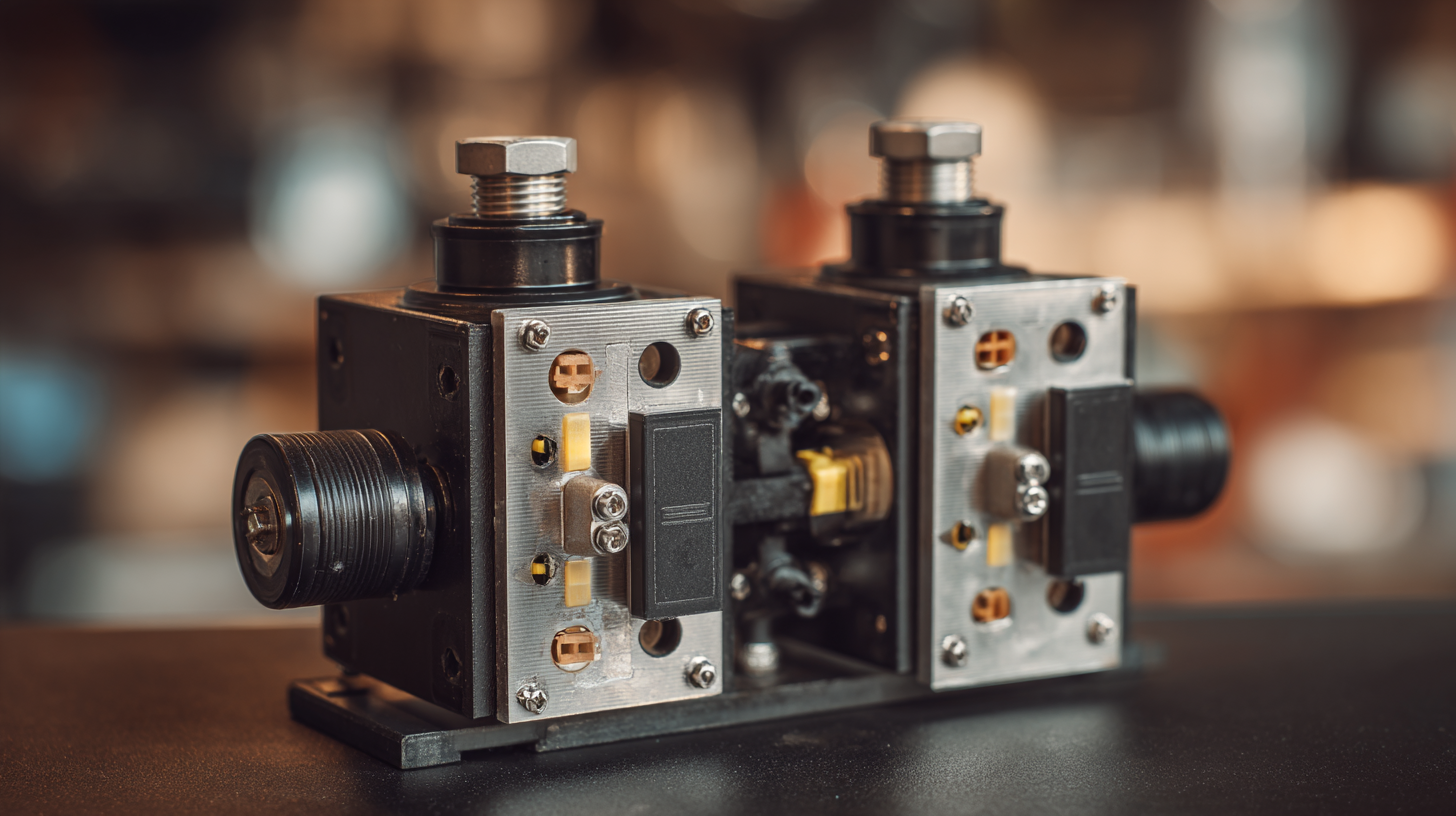

Another important factor to consider is the feedback system. Servo motors can come with various types of feedback mechanisms, such as encoders, resolvers, or potentiometers. Depending on your application, you may require a high-resolution encoder for precise position control, or a more straightforward setup could suffice.

**Tip:** Evaluate your control system's compatibility with the feedback devices available. This will help in making a well-informed decision that ensures seamless integration into your existing control architecture.

In the realm of robotics and automation, servo motors play a pivotal role in enhancing precision and performance across various applications. As industries continue to innovate, a comparative analysis of the top servo motor brands reveals significant variations in technical specifications among models available today. Key factors such as torque, speed, and feedback systems greatly influence the selection process for engineers and manufacturers aiming for optimal efficiency in their projects.

A closer look at the leading brands highlights their unique strengths in the market. Companies specializing in high-end automation often provide advanced servo motors with superior control capabilities, making them ideal for complex, precise operations. Meanwhile, brands focused on affordability deliver dependable performance for less demanding applications, ensuring that businesses of all sizes can access necessary technology. As the landscape of robotics evolves, understanding these specifications and brand differences will equip decision-makers with the knowledge to choose the right servo motors that align with their operational needs and future aspirations.